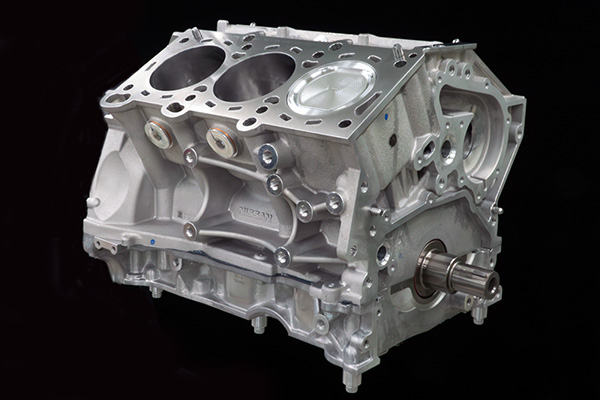

(ENGINE) SHORT BLOCK VR38 4.3L STEP Pro+

ENGINE BLOCK COMPONENTS

【SHORT BLOCK VR38 4.3L STEP Pro+】

VR4.3L STEP Pro + short block is strengthened for stages that require even higher torque

Concept

Capable for high torque, the VR43 STEP Pro+, contains special designed I-beam con-rods which have a high buckling strength compared to the H-beam con-rods. In addition to the specifically designed crankshaft and to further enhance the torsional rigidity. The pin diameter have been enlarged, and by adopted an asymmetrical design, the cross sections between pins #5 and #6, where stress is the highest, have been reinforced.

In response to the increased weight of the pin section, the counterweight was redesigned to improve the balance ratio.

Features

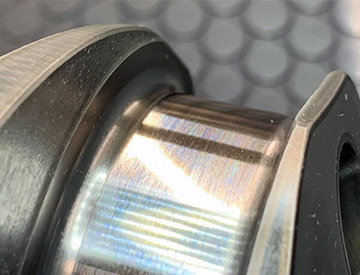

- As with the STEP Pro, the material for the crank is made of high-end racing grade nitriding steel. Exclusively for the STEP Pro +, the crank is treated with ion nitriding, which increases surface strength and toughness that are required of high cycle performance crankshafts.

- By increasing the inside corner radius to 3.5 and enlarging the crankpin to D57, the structural torsional strength is improved.

- The newly developed, billet I-beam con-rods improves bucking strength by 26%.

- The front end of the crankshaft is extended 10mm to prevent crank pulley fretting.

- Designed specifically for the STEP Pro+, the pistons are coated with a special double layer coating, which is effective for both high-load and high-speed sliding.

- HKS original oversize main stud bolts are used

- Chrome Molybdenum is used to create the #2 and #3 journals to increase durability.

- Line boring process is done to ensure the roundness of the main journal

- The main bearing and connecting rod bearing were selected after numerous tests.

-

Crank pin diameter and inside corner radius are enlarged to increase torsional rigidity.

(Only available for STEP Pro+) -

Newly developed Billet I-Beam connecting rods that improves buckling strength by 26%.

(Only available for STEP Pro+) -

Double-layer coated lightweight billet piston made from highly hear resistant A2618 alloy (Only available for STEP Pro+).

-

I断面コンロッドに合わせて専用のオイルジェットを3Dプリンターで制作

-

#2・3のベアリングキャップをクロモリ材で作り替え強化しラインボーリング加工で精度向上

諸元

| HKS 4.3L | 純正 | |

|---|---|---|

| ボア | 95.5mm | 95.5mm |

| ストローク | 99.0mm | 88.4mm |

| 圧縮比 (t=0.8) | 8.6 | 9.0 |

| 許容回転数 | 7,400rpm | 7,000rpm |

| 排気量 | 4,255cc | 3,799cc |

SHORT BLOCK VR38 4.3L STEP Pro+

| ブロック加工内容 | #2・3クロモリ材キャップ |

|---|---|

| クランク干渉部の逃がし | |

| メインベアリングネジサイズのアップ | |

| ラダーキャップの穴拡大、座繰り | |

| ジャーナル穴のラインボーリング | |

| ホーニング | |

| メインボルト | HKS M12スタッドボルト (625+) |

| ピストン | HKS 削り出し(専用2層モリブデンコート) |

| コンロッド | Pro+専用 HKS削り出し I 断面 |

| オイルジェット | Pro+専用 3Dプリンター製造 |

| クランクシャフト | Pro+専用 窒化鋼削り出し イオン窒化熱処理 ピン径拡大φ57、フィレットR拡大品 ダンパー取り付け部延長 |

| メインベアリング | ACL |

| コンロッドベアリング | ACL(幅狭加工) |

| クランクプーリー | VR43専用ダンパー |